For the last few years we've been storing our patio furniture and the tractor/snowplow in an old metal garden shed plus a small shelter. Both were starting to fall apart - truthfully, the shed was barely standing anymore.

So, for the last few weekends we've been working on a new oversized storage shed. It's about 60% finished right now and looking pretty good.

We started by building a platform of 2x6s topped with plywood. Chloe stayed close by while the guys put up the 2x4 walls.

I spent a Sunday afternoon building roof trusses. By the end I was cold and my back was killing me, but I'm pretty proud of them.

The trusses at the front and the rear of the shed are different as each will have a window in the center.

Once the roof was ready to be added, Tom and a neighbor moved the shed into place at the back of our property. If only I had pictures of that. They wrangled it up onto a 30 foot trailer and then backed the trailer into the clearing and set the shed down in a spot that Tom had cleared and leveled with gravel.

Tom attached the trusses and covered them in plywood. He'll be adding corrugated roofing panels on top next weekend.

The siding for the shed is pressure treated spruce. It's hung in an overlapping pattern. First a row of boards was attached to the walls using a 2x4 for a spacer.

Then a second row of boards was added to fill the spaces. The boards are air nailed to the framework and to each other so that it stays tight.

Hopefully it will only take another weekend or two to finish it. Thank goodness, as we've already had our first big snowstorm!

Pages

▼

Oct 26, 2018

Autumn/Halloween Decor House Tour

Rumour has it that there is another round of snow coming in this weekend, so before everything gets covered in white, I managed to get some Autumn/Halloween decorations out.

How about a tour?

In December I hang a wreath on the main bathroom door. Tom christened it "The Christmas Pooper" the first time he saw it. I guess with this wall hanging it'll be "The Halloween Pooper".

The front door is decorated with an autumn wreath. I usually take whichever wreath strikes my fancy at the moment (I have a few) and add a pumpkin welcome sign.

How about a tour?

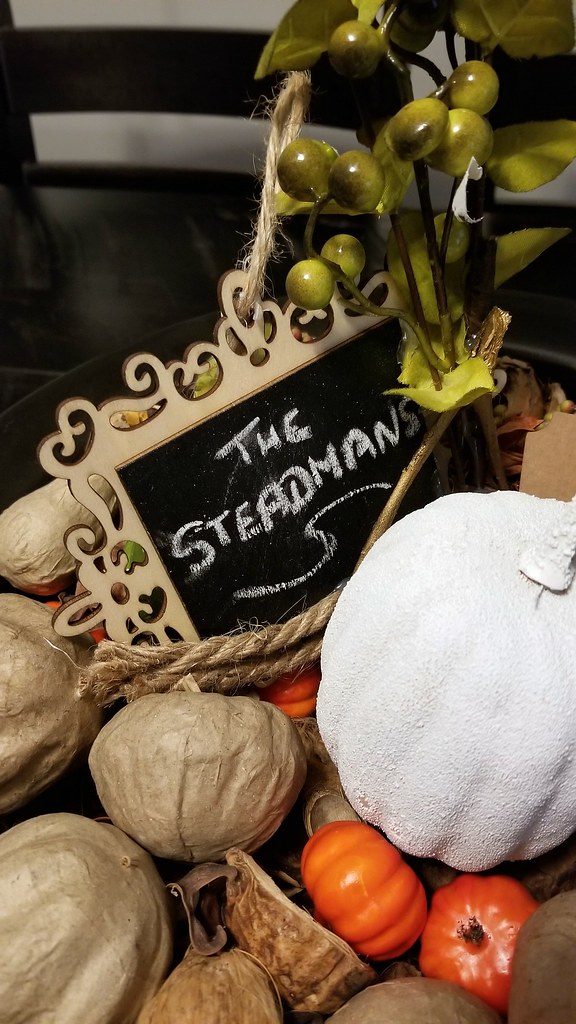

I like the neutrality of the papier-mache pumpkins and mini gourds, with little pops of orange and white.

My aunt made chalkboard signs for us all at Thanksgiving. It fits in perfectly with the mix and match décor.

And there's one more pumpkin in the kitchen. This is one of my dryer vent pumpkins, recovered with an old sweater, then decorated with twine and vines.

In December I hang a wreath on the main bathroom door. Tom christened it "The Christmas Pooper" the first time he saw it. I guess with this wall hanging it'll be "The Halloween Pooper".

The front door is decorated with an autumn wreath. I usually take whichever wreath strikes my fancy at the moment (I have a few) and add a pumpkin welcome sign.

And we have a jack-o-lantern stack in the planter. I love these guys. Pay no attention to the partially-dead plants though. You can pretend it's part of the theme if you'd like.

Just a few simple things to make the house more festive.

Oct 23, 2018

Ironing Board Holder (DIY)

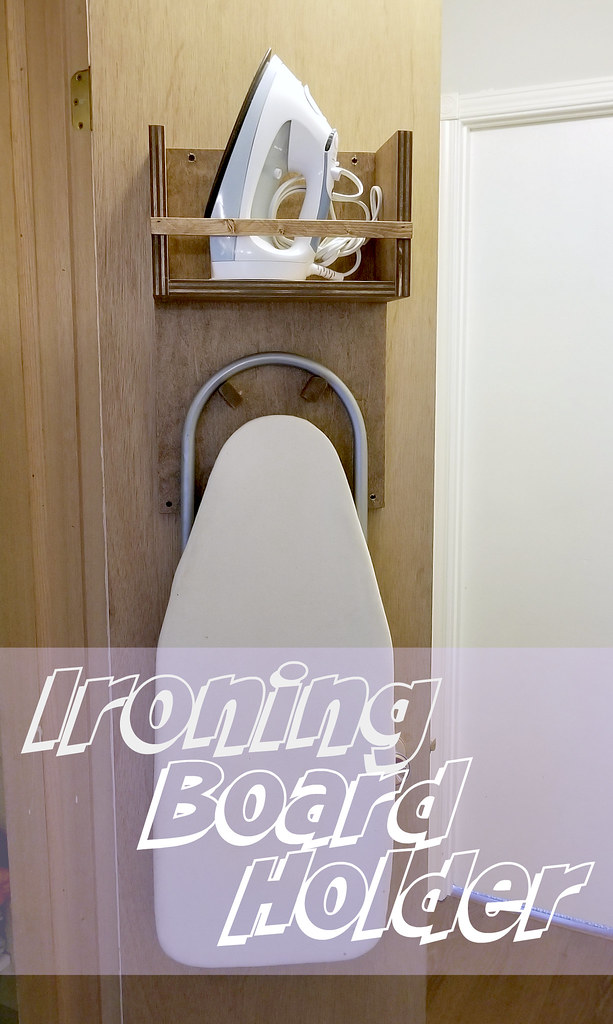

I'm trying to be a little more organized around the house - using every possible nook and cranny for storage. A prime example: our linen closet is extremely small - I've had to pare our sheets and towels down to just the necessities - but the iron and ironing board still didn't have a dedicated space.

I took this design idea from Ana White and tailored it to our house. The great thing about it is that it cost me nothing - it was made entirely from scrap wood - but it wouldn't cost more than $20 if you had to buy the material.

We have a compact tabletop ironing board so it fits perfectly on the inside of the linen closet door. I probably should have realized earlier that I could hang it there. And the door casing is deep enough that the shelf for the iron doesn't interfere with the shelves inside.

Materials needed:

3/4" plywood (mine has a birch veneer)

1" x 1.5" pine board (or dowels)

1" x 1/4" pine trim

1-1/4" brad nails and/or screws

Tools used:

Air nailer (with compressor)

Drill/Driver

Measuring tape

Ruler

Miter Saw

Table Saw

Cut List:

1 - 12"x 20" plywood (back)

1 - 10.5"x 5" plywood (shelf bottom)

2 - 7.5"x 5" plywood (shelf sides)

2 - 2" pine pegs or dowels

1 - 12" pine trim

To build:

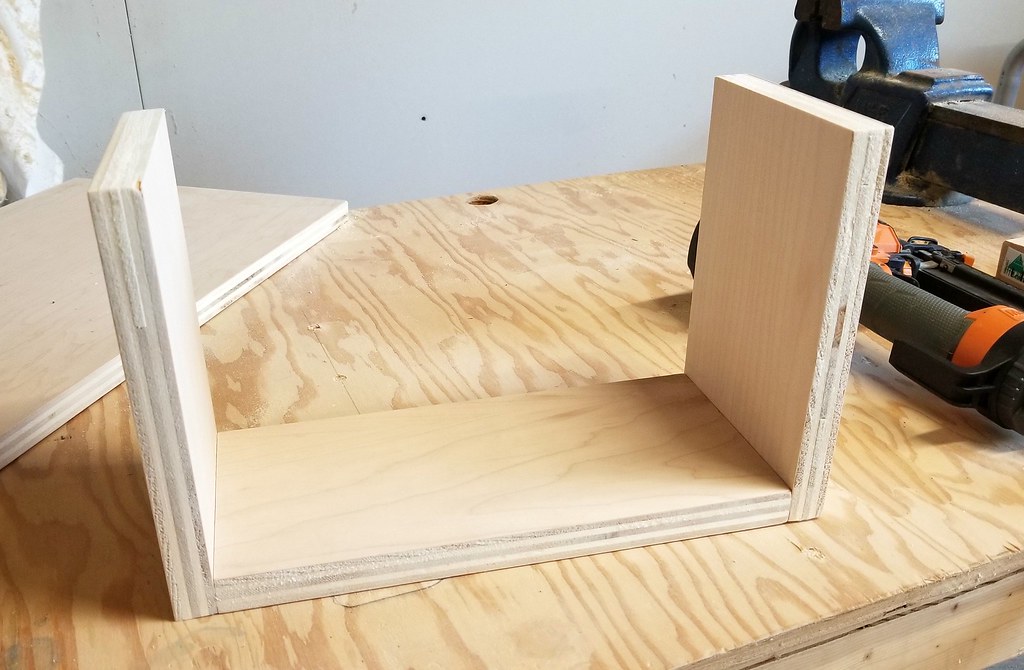

Attach the sides of the shelf to the bottom with either countersunk screws or brad nails. The bottom should be sandwiched between the sides and should be flush.

Attach the shelf pieces to the back with countersunk screws. All outside edges should be flush.

The board I found in the scrap pile for the pegs was flat on the bottom and rounded on the top. I have no idea where it came from or what it was used for, but it was ideal for this project. At first I was going to attach the pegs in a straight line like on the original plans, but due to the shape of the ironing board "leg", it made more sense to angle them. The curved edges of the tops of the pegs fit the curve of the leg perfectly.

Place the pegs or dowels in position and trace around them. Taking a very small drill bit, drill a hole through the back board in the centre of each traced area. This gives you a reference point for the screws when you attach them from the back. Glue the pegs to the board to hold them in place while you're working on them. (I used a couple of drops of Krazy Glue).

Screw the pegs to the board from the back, using the drilled hole as reference, as mentioned above. Since my pegs were going to be at an angle, I needed two anchor points for each, to keep them from twisting around. My ironing board is very light and the pegs are small, so I used two brad nails in each peg instead of screws.

Attach the trim to the front of the shelf a few inches up from the bottom using brad nails or screws. This strip of wood keeps the iron from falling off the shelf when the door is opened and closed.

My shelf was stained with Minwax stain in Special Walnut. Two coats and then buffed with a soft cloth.

The final step is hanging the holder. I mounted it to the inside of the linen closet door with a screw at each corner of the back board. If your iron or ironing board are heavy, you may want to use anchors behind the screws.

Oct 19, 2018

Autumn Projects Roundup

We had our first snowfall yesterday morning, which I think means we are cruising right past autumn and moving on to winter here. But for those of you lucky enough to still have fall-like weather, here are some seasonal crafts and recipes you may have missed. (Click on an image to go to the original post.)

~~~~~

Mason Jar (Flameless) Candles

~~~~

~~~~

Acorn & Pinecone "Tree" Centerpiece

~~~~

~~~~

Reversible Scarecrow/Snowman Sign

~~~~

~~~~

Porch & Mantel Decor

~~~~

~~~~

Dryer Vent Turkey and Pumpkin Centerpieces

~~~~

~~~~

Pumpkin Cheesecake Trifle (No need to bake!)

~~~~

~~~~

Oct 15, 2018

Adding a Wooden Fence to your Property

So, the journey continues to add more curb appeal to our property. I've always felt that the front of our house, including the yard, was too plain. The plans I carry around in my head include more trees, shutters on the windows, and possibly a stone façade. And the house itself is fairly close to the road so it really needed something to provide a visual break.

After mapping out the fence with stakes and string, we rented a mini skid-steer with an auger attachment and dug the post holes. The first few were easy, but we did hit rocks in most of them after that. It only took a couple of hours to do all fourteen holes. I can't imagine how long it would have taken if we'd had to dig them by hand.

Once all of the holes were dug and the loose dirt cleaned out - that part was done by hand while lying on the ground, scooping, scooping, scooping - we positioned the 6x6 posts and filled the holes with rapid-set concrete. We started by putting some gravel down to provide drainage, then the post, which we leveled with two temporary crosspieces facing different directions. That corner post level was a God-send!

We then alternated adding concrete, gravel, and water until the hole was slightly overfilled (to allow for settling). The concrete hardened fast enough that in 20 minutes we could remove the crosspieces, to be used on the next post.

Once the posts were in, we hung the 2x6 horizontal rails with concealed-flange joist hangers that I spray painted a glossy black. These are joist hangers that you would use when building a house or deck. We wanted the rails to be centered on the posts, but didn't want to have to drill through every post to hang them. These were perfect, and the black colour makes them look like high-end hardware.

The screws attaching the joist hangers to the posts are hidden behind the rail ends, and then low-profile cabinet screws connect the hangers and rails. We built a simple jig from scrap wood to ensure that each hanger was centered on the post. The cabinet screws have a washer head that gives an upgraded look.

Our lot slopes to one side, so we had to eyeball the rail placement so that they look level, even though they aren't. I spent a lot of time standing out on the road, squinting and calling out for adjustments. However, we did use a spacer between rails so that they remain the same distance apart from section to section.

The final step was to cut off the tops of the posts. We cut them a little at a time so that they didn't end up too short. I think we're going to keep the look streamlined and leave the tops squared off, but I also think I'd like them to be about an inch shorter than they are right now.

Before cutting:

One thing I do know is that the fence looks fantastic with the trees behind, especially now that the leaves are changing colour. The natural wood fence warms up the look of the front yard and gives a solid framework to the whole property.

After mapping out the fence with stakes and string, we rented a mini skid-steer with an auger attachment and dug the post holes. The first few were easy, but we did hit rocks in most of them after that. It only took a couple of hours to do all fourteen holes. I can't imagine how long it would have taken if we'd had to dig them by hand.

Once all of the holes were dug and the loose dirt cleaned out - that part was done by hand while lying on the ground, scooping, scooping, scooping - we positioned the 6x6 posts and filled the holes with rapid-set concrete. We started by putting some gravel down to provide drainage, then the post, which we leveled with two temporary crosspieces facing different directions. That corner post level was a God-send!

Once the posts were in, we hung the 2x6 horizontal rails with concealed-flange joist hangers that I spray painted a glossy black. These are joist hangers that you would use when building a house or deck. We wanted the rails to be centered on the posts, but didn't want to have to drill through every post to hang them. These were perfect, and the black colour makes them look like high-end hardware.

The screws attaching the joist hangers to the posts are hidden behind the rail ends, and then low-profile cabinet screws connect the hangers and rails. We built a simple jig from scrap wood to ensure that each hanger was centered on the post. The cabinet screws have a washer head that gives an upgraded look.

Our lot slopes to one side, so we had to eyeball the rail placement so that they look level, even though they aren't. I spent a lot of time standing out on the road, squinting and calling out for adjustments. However, we did use a spacer between rails so that they remain the same distance apart from section to section.

The final step was to cut off the tops of the posts. We cut them a little at a time so that they didn't end up too short. I think we're going to keep the look streamlined and leave the tops squared off, but I also think I'd like them to be about an inch shorter than they are right now.

Before cutting:

After:

One thing I do know is that the fence looks fantastic with the trees behind, especially now that the leaves are changing colour. The natural wood fence warms up the look of the front yard and gives a solid framework to the whole property.