Our favourite little girl turned 3 this year, so naturally - being the DIYers we are - we had to build something for her birthday. We had already built this bookcase/toybox for her first birthday...but then ran out of time last year and had to go the Dora/store-bought route for her second.

Now it's back to the workshop this year to build a pint-sized craft table with attached paper roll.

I first saw a children's craft table for sale online months ago and told Tom, "We should build that!" Of course he agreed - happy wife, happy life. Once we got around to planning it though it took us a week of brainstorming and many, MANY changes before we came up with a design we liked. We even took a trip to Ikea in an ice storm to look at their tables and to pick up rolls of paper - it's the only place we could find 18" rolls that weren't 1000 feet long.

We kept our table as simple as possible - clean lines, light-coloured wood, clear lacquer.

Here is a materials list if you're looking to build one of your own:

Top: 20"x 36"x 3/4" shelving

Apron:

3 - 17½"x 1½"x 3/4"

2 - 35¼"x 1½"x 3/4"

Legs: 4 - 19½"x 1½"x 1½"

Tray:

2 - 201/3"x 1½"

1 - 45/8"x 1½"x 3/8"

1 - 201/3"x 5½"x 3/8" plywood

1 - 18¾"x 21/3"x 3/8" spacer board

Tray/Paper Roll Supports: 2 - 12½"x 21/3"x 3/8"

Miscellaneous:

1 - 21" dowel

5 - ¾" magnets

2 - 1½" wooden knobs

2 - eyelet screws

3 - small metal buckets for drawing supplies (dollar store)

wood screws

finishing nails

wood glue

wood putty

sandpaper

polyurethane

brushes, etc.

paper roll

stool or chair

~~~~~~~~~~~~~~~~~~~~~~~~~~

Directions:

Since we used a full 20"x 36" shelving board for the table top, there was nothing extra to do to it besides sand it smooth - especially the edges and corners. We didn't want any unnecessary injuries happening (to us or the birthday girl).

We weren't able to find 2x2 select pine boards for the legs the day we went material shopping, so we bought a 2x4 and planed it down to size. In retrospect it might have been easier to buy 2x2 knotty pine since the grade ends up being about the same, but at least by planing the wood we knew our table legs were completely straight.

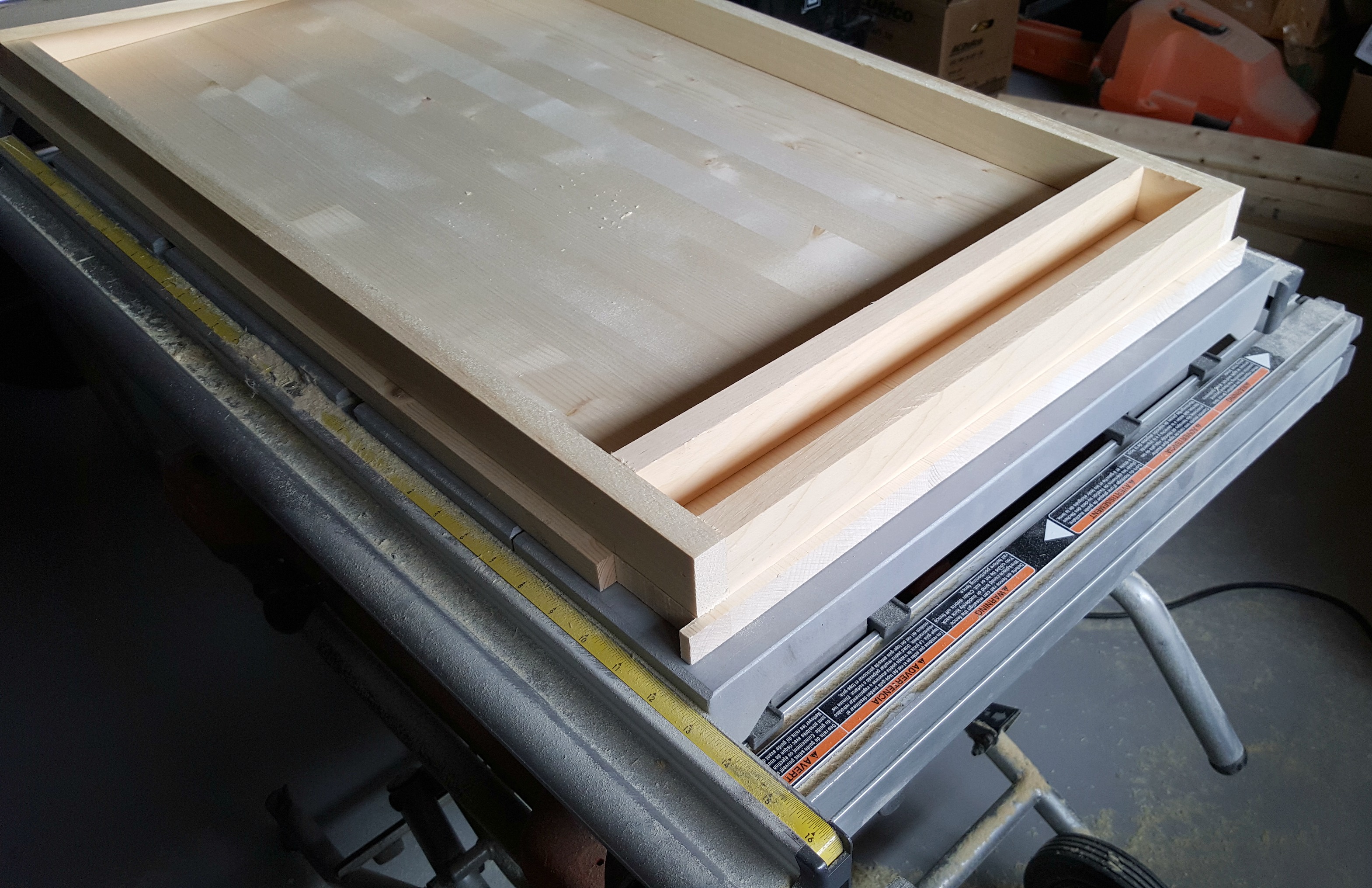

To beef up the table profile a bit and to give the legs stability, we added a 1"x 2" apron all around the outside. The apron is inset about 3/8 of an inch from the edge of the table. We joined the pieces with simple butt joints rather than mitering them, using wood glue and countersunk screws. I like the simpler look and the joint is stronger - but if the mitered joint strikes your fancy then go for it! The apron frame was then attached to the tabletop with more countersunk screws, down through the top of the table.

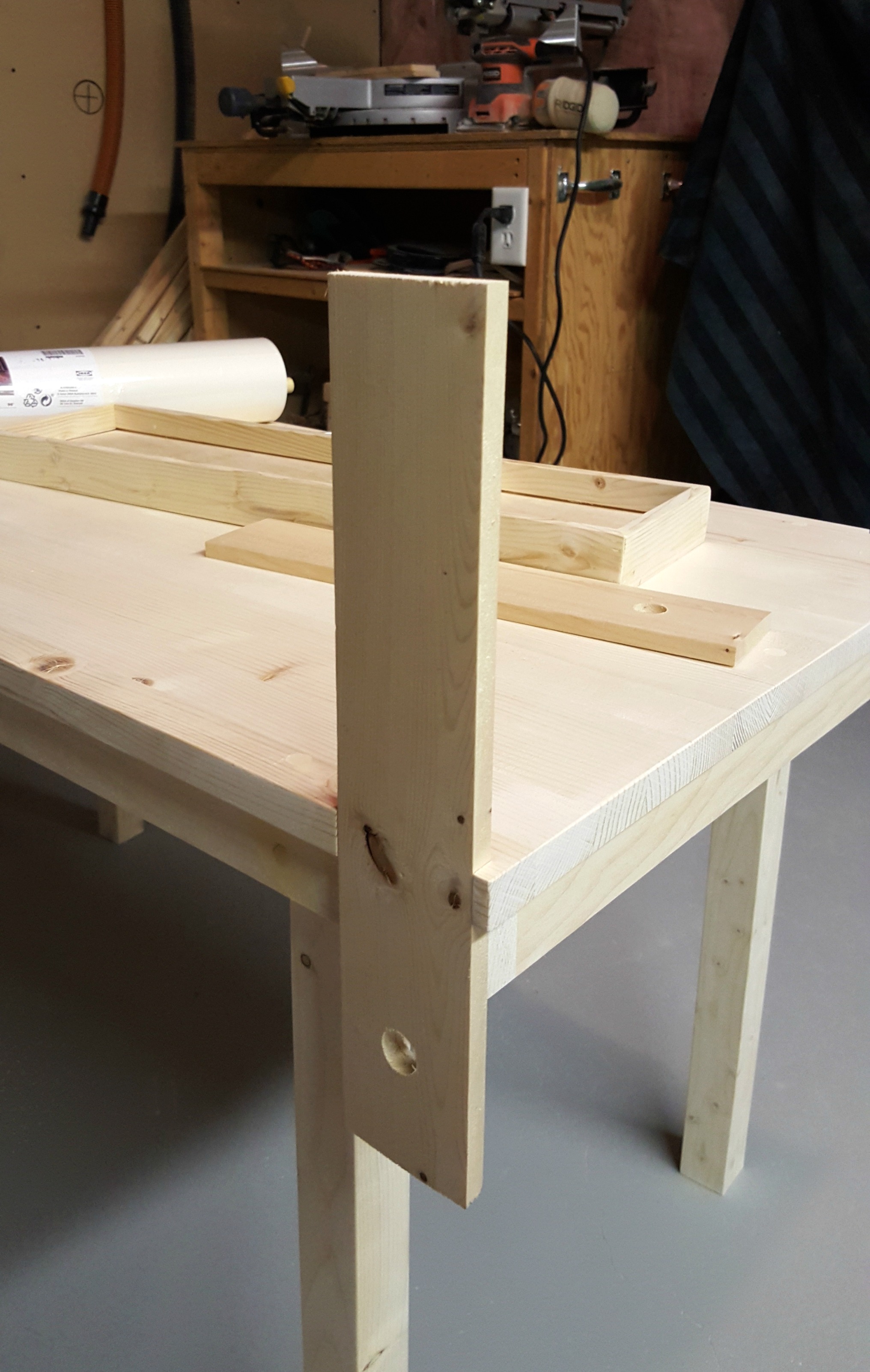

The legs were attached to the apron in each corner with two (countersunk) screws. Since the paper roll hangs below the table, the legs at that end had to be inset from the edge by about four inches. To secure these legs we added another apron piece across the underside of the tabletop, parallel to the end piece. The legs were then attached to this inner board.

There was a lot of discussion around how we were going to attach the tray and the paper roll to the table. We decided to cut a notch into each side of the table that the uprights would fit into so that we could secure it to the apron and the side of the tabletop. There are several things to consider here - How low do you want the paper roll to hang? How far do you want the roll indented from the end of the table? How high do you want the tray to be above the table? How wide do you want the supports to be?

Once you know how far in you want the roll to be and how wide the supports are, you can cut the notches into the table the same width as your support pieces. Our support pieces are 3/8" thick so that they fit snug against the apron and stay flush with the outside edge of the table.

Fun fact: the supports (and tray sides) are made from leftover boards from our board and batten project at the old house. Nothing goes to waste here!

Before cutting the supports to length we put them in place and merely slid them up and down until we arrived at a distance above and below the table that was pleasing to the eye. We drew a faint line on each support where it met the top of the table and measured/marked each for the top and bottom cuts.

Before attaching the supports to the table you'll want to drill a hole in each for the paper roll dowel to sit in. This hole should be at least twice as big as the dowel so that it is easy to take in and out when replacing the paper.

The supports can then be attached to the table. We used a couple of finishing nails just to hold them and then countersunk screws to secure them well.

The tray is made of thin lengths of wood planed down to size, with a piece of plywood for the bottom. A groove was cut along tray edge, 3/8" from the bottom. This groove is the same thickness as the tray bottom.

The sides of the tray are joined at a 45 degree angle (miter joint) so it didn't matter that the groove went all the way across, but if you are using butt joints you'll want the groove to stop just before the end so it doesn't show on the outside. You'll likely want to practice on some scraps first as that can be tricky.

Taking three of the tray sides, we made sure the groove was lined up all the way around, then glued and nailed them together with finishing nails. The tray bottom then slides into place and the fourth side is attached. We designed it so that the tray would hold three metal pails for markers, paintbrushes, etc. and have a separate section for loose crayons, erasers, and whatnot. To make the separate section we added a divider across the width of the tray, again securing it with glue and finishing nails.

One other piece of wood you'll need I have no idea what to call. It is a spacer piece that runs under the tray to give it stability on the bottom and to keep the upright supports in place. This piece of wood will be the same thickness as the lip under the tray bottom (so that it sits flush when in place) and is the length of the visible tray bottom minus the thickness of the upright supports. The supports will end up being sandwiched between the edge of the tray and this new spacer piece, keeping them from wobbling around.

Here is a shot of the spacer board in place (the table is upside down):

Attaching the tray to the supports required the two of us working together (!!!) One person pressed in slightly on the supports while the other fit the tray on top. Then after applying wood glue to the horizontal spacer it was pressed up into place under the tray. Using the glue gives you time to make adjustments and align everything perfectly before it sets. Once all of the pieces were in place we clamped the tray in several spots to keep the spacer board tight against the bottom. Finishing nails secured the supports to the tray.

We spent some time brainstorming a way to keep the paper flat when it was across the table. A flip-down arm would be cool, but we were afraid it would eventually get broken. And a stationary arm would mean that the paper had to be fed through each time - not so easy for little hands. We came up with the idea of magnets inset into the table and knobs with metal washers attached that the paper could then be pressed between.

Insetting the magnets is very easy. You'll need a drill bit that is the same diameter as your magnet - ours are 3/4". Mark the spot where you want each magnet to be and drill into the table slightly more than the depth of your magnet. You'll want the well slightly deeper so that there is space for the glue to expand without lifting your magnet above the table surface. Apply glue to the well and drop your magnet in, making sure it's flush. As extra insurance you could clamp the magnet into place so that it can't move while drying.

The final step was to apply polyurethane to the entire table. Or you could leave yours plain, paint it, stain it...whatever strikes your fancy. I did several coats of semi-gloss transparent polyurethane (Minwax), sanding lightly between coats. Before the final coat I gave the table top a good scrub with super fine steel wool to make it really smooth.

The knobs are simple drawer pulls with washers glued to the bottoms of them. We attached two eyelet screws to the inside of the table apron, lining them up with the magnets, and then tied the knobs to the screws with lengths of bright orange ribbon. Now the knobs can be removed, but since they are still attached to the table they're less likely to be misplaced.

The dowel for the paper roll is also from Ikea. We had originally purchased the whole paper holder with the intention of incorporating it into the table, but found that you can't mount it upside down without the paper falling out. We did like the dowel it came with though as it has small grooves at each end to keep it in place on the holder. So yeah, we ended up with a $10 dowel.

The finishing touches were some new crayons and markers - and a special message to the birthday girl. I'm pretty sure she likes it - though when we gave it to her she was more interested in playing the shell game with the buckets and a spare knob than drawing on the paper. No problem, it's all about using your imagination. :-)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~