We always have lots of little projects on the go at the same time around here. Tom is even working on his very first post - showing off his solution to our drainage issues along the side of the house.

We really only get a chance to work on renovations on the weekend, and it's been pretty hot and humid lately, so to get a break Tom decided to knock out a quick project under the shade of the deck.

Since we don't have a garage (yet), all of our tools are stored either in the basement or out in an old metal shed that's a good 5 minute walk from the house. There's nothing like hiking out and back to get a rake or shovel, only to then realize you also need the pruning shears. Or that you set down your gloves on a shelf and forgot them. And I'm not a huge fan of storing the grubby line trimmer and chainsaws in the basement - which is where they are now.

We have quite a bit of free space under the deck and 6+ feet of headroom, so it seemed the ideal place to put a tool shed. The logical spot for it happened to be where the previous owners had left a huge stack of bricks, so they had to be moved first. I was (conveniently) busy working on the bedroom ceiling, so Tom moved them all to the back of the property by himself. He'd load up the bucket of the skid-steer by hand, drive out back, unload, repeat. I've never seen him so tired. It definitely made up for skipping the gym that day.

Once the area was clear of bricks and weeds, he laid down 2 ft square patio stones to keep the shed up off the ground and away from excess moisture. He needed to cut out around the pipes for one so he chose the stone that already had a crack in it, knowing that it would probably get worse (it did). But it's at the back of the shed so it's not too obvious.

He built a framework of 2x4s, securing it to both the back wall and the stones. The frame slightly overhangs the stones on each side so that gravel can be added. Then if water does get into the shed it will run off through the gravel.

The framework for the roof is built at a slight angle - 2 inches higher at the back than at the front - so that water will run down and away from the house foundation. On top of the roof frame is a sheet of plywood, and then a corrugated roofing panel. Right now it's still open at the front, but we'll eventually add on the closure strips once they're back in stock.

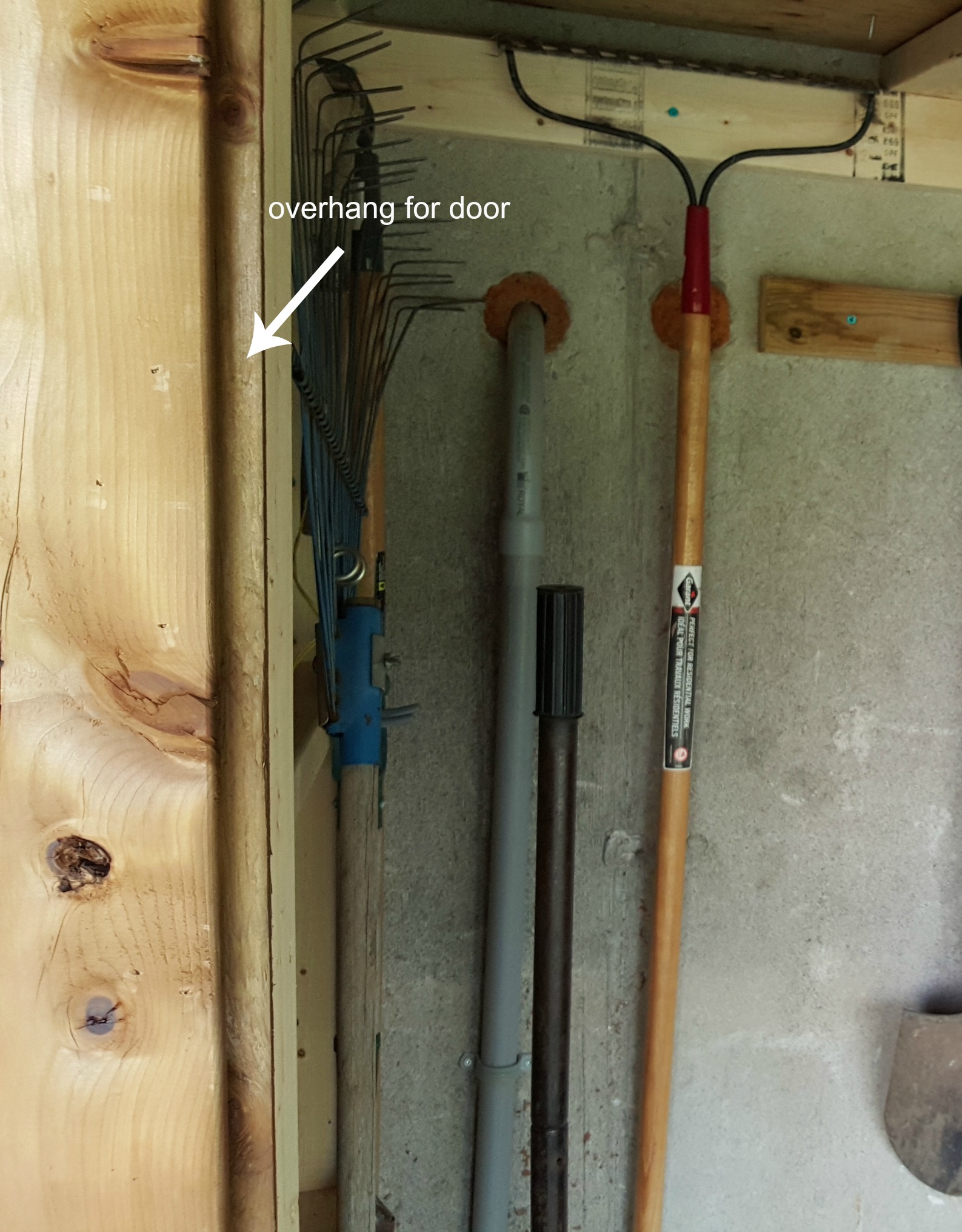

For the walls, he first put up sheets of plywood, then attached fence boards over them. You could just attach the boards directly to the framework, but the plywood provides an extra layer of protection from the elements by filling the gaps between boards. Along the front he left a bit of the frame exposed so that the door has something to rest against when it's closed.

On the inside, he needed two shelves to store the chainsaws, with room for the generator to be stored below. At first he was going to build shelves along one side front to back, but since he wanted to keep the shed as shallow as possible the shelves wouldn't have been long enough to hold the chainsaws. So he built the shelves at an angle, from the doorway on the right hand side to the back right corner. This gives him maximum shelf length and the shelf is still deep enough to hold the chainsaw. The shelves themselves are also made from fence boards on top of a 2x4 frame.

Tom built the door much the same way as the access door for our under-deck storage at the last house. He took a sheet of plywood and attached fence boards to it to match the width of the opening. He then ran the saw along the ends so that the door would match the walls of the shed. (It's slightly shorter at the top so that it doesn't rub on the roof.) Two 2x4s are attached horizontally on the inside of the door for added strength. Note that the ends of the 2x4s are angled so that they don't bump against the frame when the door is closed.

The final step was hardware. He chose some pretty decorative gate hinges and handle that are also heavy duty. The hasp has a swivel post and a hole for the padlock.

One more project checked off the list!